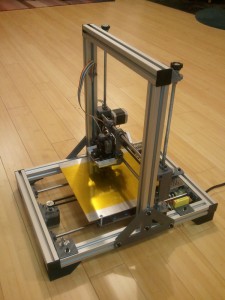

During the week, Jeremy from Lybina posted on the Australian Reprap forums that they’re now making some coloured filament. This is great news for Australia reprapers. We’ve been well-supported with very-high quality white filament from Lybina, but they haven’t had any colours available.

Even better, they were giving away some free samples. I came to the post over a day after it’d been posted, so I thought that I’d miss out for sure. I gave Lybina a call anyway, and they said that I was the first! This was pretty surprising, given that it’s free high-quality filament. I think that most people in Australia print with PLA, but it was still surprising. The only catch is that you have to pay for the postage, and report back to Lybina how the filament printed.

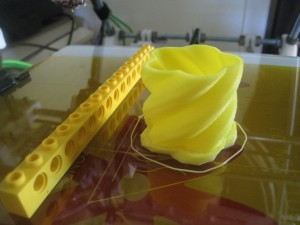

They were giving away samples of yellow, green and purple filament. I put my hand up for some yellow filament. All my printing so far has been with Lybina’s white filament, so I was pretty confident that they’re product would be good. The filament arrived by courier yesterday afternoon. Pulling it out of the bag, it looked great. Solid yellow colour.

A quick check with the micrometer showed that Lybina’s manufacturing was as good as always. First sample was 3.00mm on the long axis, 2.90mm on the short. A check on the other side of the roll had 2.95mm and 2.90mm.

For my first print, I thought that I would print out one of the ‘screwable jewellery boxes’ which I have done before. Being quite delicate, and requiring precision, I thought that they would be a good test to see how the filament performed.

When I was talking to Jeremy on the phone, he mentioned that the colours are only stable up to 220 degrees C. Since I usually do my first layer at 230 degrees C, this might have caused a problem. So I turned down the hot-end to 219 for the first layer. I made sure that the heated-bed was up to all the way up to 110 degrees (rather than my usual ‘anywhere between 100 and 110 is fine’) before I started printing. Adhesion was great, with no issues at all. For the remainder of the layers, I dropped back down to my usual 197 degrees.

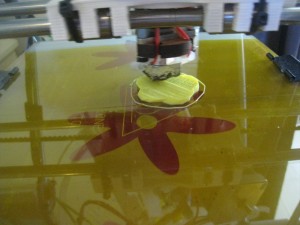

As you can see from the photos, the filament printed just fine. However, the colour was quite pallid. I was expecting much more of a ‘lego technic beam’ colour, rather than ‘pale lemon’, which was a bit disappointing. It looks like they need to use more dye.

Overall, I’d give the plastic a 10/10, but the colour a 6/10. A big thanks to Lybina for providing the free sample!