I made a little purchase in the middle of December, and there was a nice package waiting for me when I got home from holidays – Hall Effect endstops!

For those who aren’t familiar with the Hall Effect, it’s the voltage difference generated by a magnetic field. They can be used as a non-contact distance-measuring device. Hall effect sensors are used in various devices, most notably DC motors with fixed magnets, as a timing measure. The wiki page can be found here.

Its advantage is that it’s a non-contact, adjustable endstop. The problem that I have with the current endstops is that adjusting them is a pain. You have to have them attached fairly tightly to prevent them from moving during normal operation, but then trying to loosen them and adjust them by a small fraction of a mm is fiddly. This isn’t a problem for the X or Y-axes, which don’t require so much precision, but I find adjusting the Z-axis ‘just so’ to be very time-consuming and inaccurate. Lots of back-and-forth until the distance is ‘right enough’.

Its advantage is that it’s a non-contact, adjustable endstop. The problem that I have with the current endstops is that adjusting them is a pain. You have to have them attached fairly tightly to prevent them from moving during normal operation, but then trying to loosen them and adjust them by a small fraction of a mm is fiddly. This isn’t a problem for the X or Y-axes, which don’t require so much precision, but I find adjusting the Z-axis ‘just so’ to be very time-consuming and inaccurate. Lots of back-and-forth until the distance is ‘right enough’.

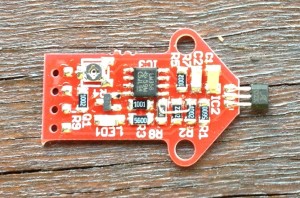

So, I purchased these Hall-effect endstops from mauk.cc. He makes these, and sells them fully assembled for 9 Euros each. At that price, I couldn’t resist giving them a go. I’m going to use this endstop to replace the Z-axis microswitch.

Due to limitations in the firmware, you can’t just set the printer to stop at a particular distance from the endstop. (Though that would be extremely nice.) It operates as a standard endstop, with an ‘on’ or ‘off’ signal. However, you can adjust (via a trimpot), the distance at which the ‘on’ signal activates. Thus, you can easily and quickly adjust the distance of the printbed to the nozzle.

Due to limitations in the firmware, you can’t just set the printer to stop at a particular distance from the endstop. (Though that would be extremely nice.) It operates as a standard endstop, with an ‘on’ or ‘off’ signal. However, you can adjust (via a trimpot), the distance at which the ‘on’ signal activates. Thus, you can easily and quickly adjust the distance of the printbed to the nozzle.